Hanse Yachts

Dear investors, dear interested parties, dear friends of water sports,

The turn of the year is already far behind us, and we hope you are all on an ideal course through 2023.

After a turbulent last fiscal year, HanseYachts is on its way to much calmer waters. There is much to report on this:

Annual financial statements and annual general meeting

Following the presentation of the Group’s annual report for the past fiscal year, the annual general meeting of HanseYachts AG was held in Greifswald on February 2, for the first time after the Corona years as a face-to-face event. In addition to a review of 2021/2022, the Management Board provided the shareholders with initial insights into the current fiscal year 2022/2023. During the subsequent tour of the shipyard guided by the Management Board, the participating shareholders were impressed by the production facilities, which had been modernized and optimized at high pressure in the past months.

![]()

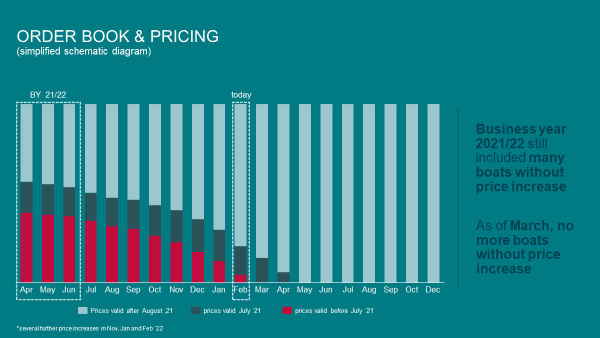

Successful price adjustments and conversion of the order book

The economic course of the company is currently benefiting particularly from comprehensive pricing measures and its order book, which remains at an all-time high with a value of more than 260 million euros: with increases of more than 30 percent, the prices for the yachts could be adjusted to the increased manufacturing costs. The entire pricing structure has also been reorganised and optimised with regard to the yacht market. In addition, special discounts were eliminated and 30 percent of the order book was converted, i.e. the prices for existing orders were also raised to the new level.

The conversion only concerned boats already ordered by dealers but not yet sold to end customers, while the prices for boats already sold to end customers remained unchanged due to adherence to the contracts. The last of these yachts are currently being produced, so that after that only boats at the current prices with sustainable margins will be in production.

The conversion only concerned boats already ordered by dealers but not yet sold to end customers, while the prices for boats already sold to end customers remained unchanged due to adherence to the contracts. The last of these yachts are currently being produced, so that after that only boats at the current prices with sustainable margins will be in production.

Our market analysis shows that as a result of the restrictions imposed by the Corona pandemic on industrial production, around 4,500 boats could not be built worldwide – this corresponds to 50 percent of the annual production of 2019. This considerable backlog has not only resulted in a historically strong order book for HanseYachts, but thus also ensures production that can be planned well into 2024 as well as the resulting turnover at prices that are profitable again.

Our market analysis shows that as a result of the restrictions imposed by the Corona pandemic on industrial production, around 4,500 boats could not be built worldwide – this corresponds to 50 percent of the annual production of 2019. This considerable backlog has not only resulted in a historically strong order book for HanseYachts, but thus also ensures production that can be planned well into 2024 as well as the resulting turnover at prices that are profitable again.

Numerous optimisation measures in production are already speeding up the passage of boats through the manufacturing process while at the same time improving quality. In addition, the separation from the French catamaran manufacturer not only relieves HanseYachts financially, but also allows all areas of the company to concentrate fully on its core brands. Normalising supply chains and less illness-related absenteeism among employees ensure improving general conditions. And in view of the recent capital increases and refinancing , which also aim to secure the financial framework until December 2025 and beyond, the Management Board is confident about the future of HanseYachts AG.

Numerous optimisation measures in production are already speeding up the passage of boats through the manufacturing process while at the same time improving quality. In addition, the separation from the French catamaran manufacturer not only relieves HanseYachts financially, but also allows all areas of the company to concentrate fully on its core brands. Normalising supply chains and less illness-related absenteeism among employees ensure improving general conditions. And in view of the recent capital increases and refinancing , which also aim to secure the financial framework until December 2025 and beyond, the Management Board is confident about the future of HanseYachts AG.

![]()

Investments in productivity and quality

HanseYachts has invested significantly in the performance, quality and safety of production. The workplaces on the production lines have been redesigned and geared towards high efficiency. Between Christmas and New Year, the last two of our four main assembly lines in Greifswald were rebuilt in record time and brought up to the same standard as the other lines. The special focus was on quality enhancement and improved processes for higher production efficiency and thus shorter lead times for the boats.

![]()

Ensuring compliance with high standards

With the introduction of lean process audits, HanseYachts has set new standards in the production lines: a shop floor management system monitors important topics such as occupational safety, production quality and efficiency as well as timely deliveries of components. Permanent checks ensure high standards and facilitate the identification of further potential for improvement. In addition, this ensures that urgent issues are known to the Executive Board by 10 a.m. at the latest and are thus addressed with high priority.

![]()

Significant quality improvement

The strong focus on production quality has led to a further significant improvement in the corresponding key figures in production. Even if the production line sometimes had to be stopped in the course of this, the short loss of speed ultimately pays off. HanseYachts has already received positive feedback from dealers on the high quality of the boats delivered recently.

![]()

Acceleration of Production

In addition to its quality initiative, HanseYachts launched an efficiency initiative. This was particularly important for the Hanse 460, as supply chain problems had led to significant delays in completion. As a result, there has been a 19% reduction in the number of man-hours required for production of HanseYachts’ current bestseller. To further reduce the number of boats not completed due to missing parts across all brands and models, the corresponding team was expanded by 20%. This has significantly reduced the number of unfinished boats to below 30. The shipyard is focused on delivering as many boats as possible for the season.

![]()

Less missing parts, but still critical issues

The increasingly normalised supply chains have also contributed significantly to the higher output. The number of components not available or available too late has now fallen by more than 50 per cent. At the same time, the situation with generators, electrics and electronics as well as engines remains tight, affecting all shipyards worldwide. For example, Volvo is repeatedly unable to produce various engines in sufficient quantities, which is currently also affecting some of HanseYachts’ motor yacht models. Delivery times of up to 18 months not only affect engines, but also stainless steel parts, upholstery and sails are repeatedly not available at short notice. In all these areas, HanseYachts is in intensive exchange with its suppliers in order to find solutions.

![]()

Modernised and optimised plant logistics

In a flagship project, factory logistics were optimised with regard to improved material tracking and shorter transport routes, and an inventory project was launched. This includes, among other things, the introduction of barcodes, which enable HanseYachts to carry out a permanent inventory and thus have a complete overview of the stocks at all times. These measures also contribute to increased production efficiency and shorter lead times.

![]()

Less sick leave, lack of skilled workers

After the unexpectedly high sickness rates in December, which led to production delays, corona infections and other respiratory illnesses at HanseYachts’ production sites in Germany and Poland have continued to decline, and production has thus recorded significantly fewer employee absences due to illness since the beginning of the year. Most recently, the rate was lower than it had been for twelve months. Nevertheless, the ubiquitous shortage of skilled workers in Germany, especially in skilled trades, remains a challenge. HanseYachts counters this shortage by employing qualified temporary workers from other countries. For example, a team from Lithuania, especially with electricians, has recently strengthened HanseYachts’ production in Greifswald.

![]()

New Fjord 41 XP with V12 outboard engines

Even before the Miami Boat Show, the market launch of the new Fjord 41 XP took place. As one of the first European series-production motor yachts, it is equipped with two 600 hp V12 outboard engines from Mercury. The new Fjord is thus aimed particularly at the North American market, where outboards are often preferred because of the many shallow water areas. With her sister, the Fjord 41 XL equipped with inboard engines, she shares, among other things, the features inherent in the Fjord DNA, such as the largest T-top and the largest cockpit in her class with double bench and two tables, as well as her characteristic design with the large hull window. Her total of 1,200 hp outboard propulsion enables the Fjord 41 XP to reach a top speed of more than 45 knots. And the more than 20 possible layouts of the interior allow a high degree of individualisation even for the highest demands.

![]()

Hanse expands new model line

Following the award-winning bestseller Hanse 460 and the Hanse 510, which is also in high demand, the new Hanse model line with its distinctive design from Berret-Racoupeau is being consistently expanded. The official presentation of the new yacht will take place in March, and she is to celebrate her world premiere at this year’s Cannes Yachting Festival. Stay tuned!

(Hanse 460)

(Hanse 460)

While in many areas the boats are dozing in winter storage, in others the season is in full swing. Many boating enthusiasts enjoy their time on the water, others can hardly wait for it to start again. And some of them are dreaming of a new yacht. That is why HanseYachts tirelessly builds our sailing and motor yachts all year round to make our customers’ dreams come true.

We wish you and your families a hand’s breadth of water under your keel at all times.

Your HanseYachts AG Investor Relations Team

Visit our Investor Relations page for further information. In addition, our Financial Calendar provides details of upcoming investor calls and participation at the next capital market conferences.